Re: Engine Oil Particles

Thank you Marco for sending in a question, and it is a good one. Let's look at something in microns to provide a better understanding. Something we are all familiar with, width of a spider web strand can be 3 to 8 microns. Okay so, that gives us a pretty good idea of particle sizing, and it is something that can easily be seen. Next, the engine oil you are using is made up of base oils and additives. They begin life separately and are mixed together to form the finished product. The bypass oil filter, does not trap the oil additives due to their molecule size. Oil analysis is examing substances of the oil sample in parts per million (ppm) and will identify the oil's additives such as potassium. In terms of metal concentrations, it is the same whether it be iron, chromium, alluminum, copper, etc. These will be particles much smaller in size than the efficiency rating of the oil bypass filter. Hope this helps answer your question. Replied by Tech Admin

Oil Bypass Filtration - How Does It Work?

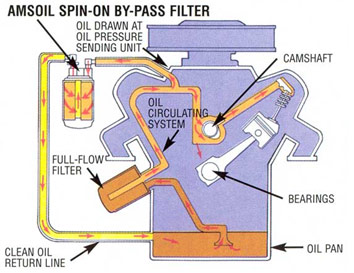

Bypass oil filtration features a secondary filter with the purpose of eliminating nearly all contaminants from motor oil. Bypass filters have high capacities and eliminate much smaller particles than full-flow filters, including soot. Bypass filters reduce engine wear and increase oil volume, but their high efficiencies mean they also have higher restriction and must be used in conjunction with a full-flow filter.

Bypass filters operate by filtering oil on a "partial-flow" basis. Approximately 10 percent of the oil pump's flow capacity at any one time and trap the extremely small, wear-causing contaminants that full-flow filters can't remove. Bypass filters have a high pressure differential, causing the oil to flow through them very slowly and allowing for the removal of smaller contaminants. It is called bypass filtration because the oil flows from the bypass filter back to the sump, bypassing the engine. This continual process eventually makes all the oil analytically clean, reduces long-term wear and can dramatically extend oil drain intervals.

Single Remote or Dual Remote Systems

AMSOIL offers two types of bypass systems: Single-remote and Dual-remote. The systems are equally efficient, and the real difference is the location of full-flow filter.

Single Remote System

The AMSOIL Single-Remote System is convenient to install; it does not require relocating the full-flow filter. It also takes up less space, which is often the biggest issue when installing a bypass system. With the Single-Remote System the oil is diverted from its normal circuit:

- From a pressurized oil port

or - Through a filter adapter/oil filter cap (available for purchase for specific applications)

The oil is then pumped through the bypass filter and returned to the oil pan. There are two ways to return the oil to the pan:- Drill into either the oil pan or the rocker arm/valve cover to return the oil

or - Modify an oil filler cap/purchase a replacement oil filler cap from AMSOIL (available for purchase for specific applications)

- Drill into either the oil pan or the rocker arm/valve cover to return the oil

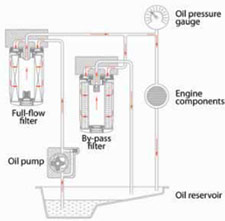

Dual Remote System

The AMSOIL Dual-Remote System is convenient for servicing filters, placing both the full-flow filter and bypass filter on the same dual-mount. If you have the room in your engine compartment, this is a good option. A spin-on filter adapter fits onto the filter mount at the engine block, through which the oil is both taken and returned. The oil flows through both filters, and the oil returns to the system through the filter adapter.

Full Flow Filter vs Bypass Filter

Full-flow filters are more open and free-flowing than bypass filters so they are able to support the flow of oil that lubricates the engine. Because they are freer-flowing, they are less efficient at removing small particles. AMSOIL Ea® Full-Flow Filters can efficiently remove particles down to 20 microns.

Bypass filters only filter a small percentage of the system’s oil at any given time. Denser, more efficient filtration media provides improved small-particle removal. Ea Bypass Filters efficiently remove contaminants (98.7 percent efficiency) down to 2 microns.

Used together, full-flow and bypass filters provide comprehensive wear protection against both large and small particles, as well as both short-term and long-term wear. In addition, filter capacity is increased, and the life of the filters is extended.

Oil-Bypass Questions

You have additional questions about Oil-Bypass Systems, visit the bypass filtration faq page. Additional information is available on installing an oil-bypass system.

Benefits A Bypass System Can Provide

Efficient Small Particle and Soot Removal

The high-efficiency AMSOIL Ea Bypass Filter element is also an effective soot-removal device. The filter element is composed of a highly efficient media, which increases soot-removal efficiency when the bypass filter is used in conjunction with a standard full-flow filter.

Significantly Extended Engine Life

The majority of engine wear is caused by particles in the 5-20 micron range. Because AMSOIL Ea Bypass Filters effectively remove contaminants down to 2 microns, your engine receives the ultimate in wear protection. Less engine wear keeps the engine in better physical condition, extending its life.

Increased Filtration Capacity and Life

An additional filter adds additional opportunity to filter particles out of the oil. The full-flow filter removes larger particles down to about 20 microns, while the bypass filter removes the smaller particles down to 2 microns. Working together, these filters provide next-level protection for your engine.

Improved Oil Cooling

With increased oil capacity, the oil filtration system contains more fluid through which it can disperse heat from the engine. This allows the engine and the oil to run cooler.

Increased Fluid System Capacity

By installing an additional filter, the engine system has the capacity to hold more oil. The increased fluid capacity and filtration life ensures the equipment constantly runs on highly filtered oil. Engine efficiency is increased, providing extended engine life.

Reduced Maintenance Costs

AMSOIL Bypass Systems provide a dramatic increase in engine protection, helping you avoid costly repairs associated with engine wear.

Dramatically Extended Drain Intervals

Ea Bypass Filters can help users extend their oil drain intervals. AMSOIL recommends using oil analysis when extending oil drain intervals.

Canada

Canada United States

United States

Reviewed by Marco:

Engine Oil Particles

Great article, very informative. I am confused with one aspect of bypass filtration. I just installed the Amsoil BMK23. One benefit of engine oil analysis is to determine wear metal concentration which could be used to determine potential component wear. If the bypass filter can remove particles from 2 microns or larger, if I was then to have an oil analysis completed, my oil results would be very good - low values on metal wear. Any potential evidence of metal wear is being filtered out. Am I interpreting this incorrectly?