What is grease?

In maintaining my automobile, I have lubricated chassis points with grease, re-packed wheel bearings. Used grease to lubricate the window tracks, but what is grease made from, and what are the different types of grease.

Grease is a semi-solid lubricant with unique properties that differentiate it from typical oil lubricants. Grease is preferred over oil in certain applications. Grease must continually cling to and lubricate moving parts despite gravity, centrifugal force and extreme pressure.

Grease is used anywhere a continuous flow of oil cannot reach. Open bearings and chassis fittings are common application points. Grease has the advantage of reducing the need for re-application of lubricant. It stays in place better than many other lubricants and helps prevent contamination.

A number of factors can affect the shelf life of stored grease. Contamination is the most common issue. Water intrusion and the migration of water vapor can cause grease to degrade, resulting in reduced performance. The ideal temperature for grease storage is between 32°F and 85°F. Grease should be stored indoors whenever possible to reduce the potential for damage from environmental contamination and temperature fluctuations.

Components

Grease is mostly base oils with some additives and thickeners. Base oils have the greatest influence on the performance characteristics of the final grease product. Base oil viscosity, whether thin or thick, is chosen based on a variety of operating parameters.

Grease Base Oils, Additives and Thickeners

Base Oils

Base oils are the lubrication medium and help with wear protection and corrosion resistance. The choice of base fluid may be mineral oil, synthetic oil or any fluid that provides lubricating properties. In general, the base oil portion of a grease performs the actual lubrication. A lighter, lower-viscosity base oil is used to formulate low temperature greases, while a heavier, higher-viscosity base oil is used to formulate high-temperature greases.

Additives

The functions of grease additives are to:

- Boost the positive properties of existing grease and lessen its defects

- Inhibit oxidation and rust

- Provide anti-wear, extreme-pressure and friction-reducing agents

It is common to find graphite or Moly additives used to limit friction and wear. These additives protect engine components from the stresses of towing heavy loads. They do not create the destructive chemical reactions evident from other additives. Performance requirements, compatibility, environmental considerations, colour and cost all factor into additive selection.

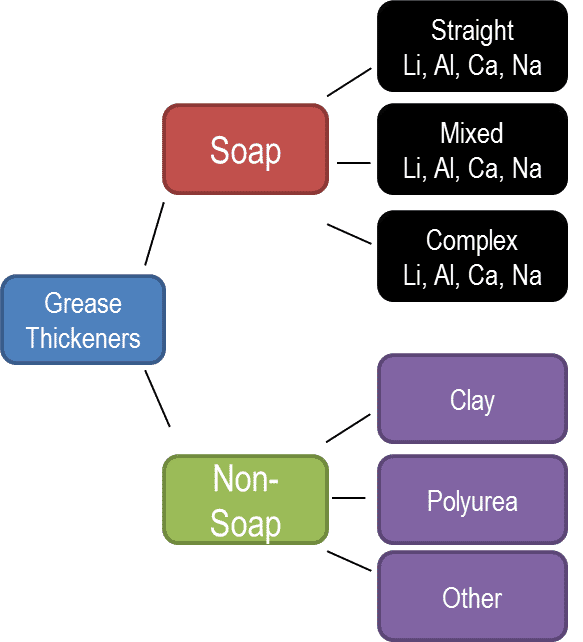

Thickeners

Combined with base oils, grease thickeners create a solid to semi-fluid structure. The function can be compared to a sponge gradually releasing its liquid when squeezed. Mechanical shear and heat induce the release of its hold of oil.

Metallic soap, the main thickener in grease, is composed of:

- lithium

- aluminum

- polyuria

- sodium

- calcium

- clay

The fiber structure provided by the metallic soap determines the mechanical stability and physical properties of the finished grease.

To enhance the grease's performance characteristics (including dropping point and load-carrying ability), a complexing agent may be added to the soap thickener to convert it to a soap-salt complex thickener. Greases formulated with soap-salt complex thickeners are referred to as "complexes" and include lithium complex and calcium-sulfonate complex greases.

Today’s most popular grease thickeners are complex formulas with high dropping points and advanced load-carrying capabilities.

Lithium and Lithium Complex Greases

are widely used and very robust; they account for at least 50 percent of domestic grease production. These greases have excellent shear stability, strong high- and low-temperature characteristics, resistance to softening and leakage and moderate water resistance. Additives are used to improve their washout- and corrosion-resistance. The generally well-rounded performance of lithium and lithium-complex greases has made them the product of choice for industrial and manufacturing environments.

Because lithium-complex grease can withstand higher temperatures than simple lithium grease, AMSOIL offers a number of high-speed, high-temperature lithium-complex greases for a variety of applications, including AMSOIL High-Viscosity Lithium-Complex Synthetic Grease, AMSOIL Synthetic Polymeric Truck, Chassis and Equipment Grease and AMSOIL Semi-Fluid Synthetic EP Grease.

Calcium, calcium-complex and calcium-sulfonate-complex greases

are known for their excellent washout- and water-resistance properties. Additives can provides these greases with strong resistance to corrosion, making them excellent for wet applications. Simple calcium grease is best used in low- to moderate-temperature applications and has acceptable stability at moderate temperatures. Calcium-complex and calcium-sulfonate-complex greases have inherent extreme-pressure and load-carrying capability, as well as temperature limits similar to those of other complex greases, making them desirable as multi-purpose greases. These greases are typically used in high temperature industrial and automotive bearing applications and have more recently been formulated for use in food-grade applications.

Since they excel over other calcium greases in extreme-pressure applications, AMSOIL provides a number of synthetic calcium-sulfonate-complex greases including AMSOIL Synthetic Polymeric Off-Road Grease, AMSOIL Synthetic Multi-Purpose Grease, AMSOIL DOMINATOR Synthetic Racing Grease, AMSOIL Synthetic Water-Resistant Grease, AMSOIL Arctic Synthetic Grease and AMSOIL Synthetic Fifth-Wheel Grease.

Aluminum and aluminum-Complex Greases

are recognized for their excellent water resistance and inherent rust, corrosion and oxidation resistance. At temperatures above 79°C(175°F), (simple) aluminum grease loses its shear stability and pumpability, while aluminum-complex grease has a maximum useable temperature of 177°C(350°F). Aluminum-complex grease is used for rolling-element and plain bearings, steel mill roll-neck bearings and high-temperature industrial applications. Some formulations of aluminum-complex grease can be used in food processing machinery. Aluminum-complex thickeners are used in AMSOIL X-Treme Synthetic Food Grade Grease.

Polyurea Grease

a commonly used non-soap grease is used in industrial rolling-element bearings, automotive constant velocity(CV) joints and other ball-bearing applications. These greases provide impressive extreme-temperature performance, making them effective over a wide range of temperatures. They have inherent oxidation and wear resistance and good work stability. The durability of polyurea greases makes them well-suited for seal-for-life components.

Because most AMSOIL synthetic greases are manufactured for consumer use, no AMSOIL greases feature polurea thickener.

Bentonite(clay-based) Grease

another common type of non-soap grease, is usually used in extremely high-temperature applications because it has no melting point. Bentonite greases' maximum temperature is limited by the evaporation of the base oil. These greases have excellent water resistance but require additives to increase oxidation and corrosion resistance. Because bentonite greases can leave a residue at elevated temperatures, the applications with which they are used require frequent lubrication.

Bentonite greases are most often used in some high-temperature bearings and in areospace applications where temperatures are extremely hot. AMSOIL does not offer a Bentonite Grease.

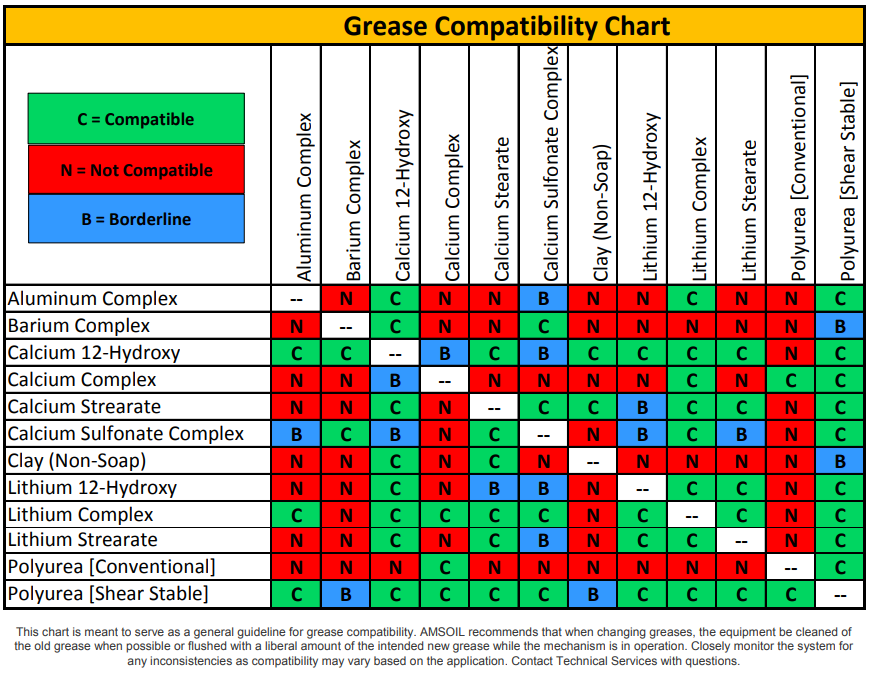

Compatibility

Mixing greases that contain different thickeners is not recommended. Ensure compatibility or simply clean out the old grease before re-application. Liberal application of new grease can help push the old product out, making it easier to access should you choose to remove it.

If you are replacing grease with new grease, you will want to pay more attention to that application to watch for issues like grease softening and base oil dropout. Reduce the maintenance interval between greasing for a while to ensure you do not have performance issues resulting from incompatibility.

Standards

In 1939, a standard classification for grease consistency was developed by the National Lubricating Grease Institute (NLGI) based on penetration test numbers. It remains widely used today. Softer grades are often used for improved pumpability or low-temperature service, while harder grades are used where leakage or sealing are particular concerns.

- NLGI No. 000 (thin, likely pourable)

- NLGI No. 00 (Semi-Fluid, like Applesauce)

- NLGI No. 0 (Very Soft, like Brown Mustard)

- NLGI No. 1 (Soft, tomato paste)

- NLGI No. 2 (peanut butter, most commonly used consistency)

- NLGI No. 3 (Firm, like vegetable shortening)

- NLGI No. 4 (Very Firm, like Frozen Yogurt)

- NLGI No. 5 (Hard, like Smooth Pate)

- NLGI No. 6 (Very Hard, hard bar)

Grease is also classified by performance:

- LA and LB (chassis grease)

- GA, GB and GC (wheel-bearing grease)

Use this information and these questions to help you determine which AMSOIL grease might be best-suited for an application. This is not intended to be the only information used to make recommendations. Research the equipment, investigate the data sheet of the current product to decide whether it is suitable for the application and then look at the AMSOIL product line to determine whether we have a product better suited for the application.

There isn’t an industry-standard guide for grease, so it’s your task to find suitable grease products. The more you know about the application, its operating environment and the speed and loads it’s likely to experience, the better off you will be.

Some equipment manufacturers provide grease specifications, which is extremely helpful. It is critical that you ask customers how they settled on the grease they use today and whether they have any issues with that grease. It’s common for customers to claim they don’t have issues. It’s your job to discover whether their issues are masked by historical practices and lack of grease education.

AMSOIL Grease Product Line-up

AMSOIL offers premium synthetic grease for a wide variety of applications, including over-the-road, off-road, automotive, racing and industrial. They are engineered from high-quality synthetic base stocks for optimum lubrication and their thickeners provide the necessary physical characteristics for enhanced durability and stability. Advanced AMSOIL additive packages enhance performance and deliver exceptional protection.

AMSOIL Synthetic Multi-Purpose Grease effectively reduces friction and wear, providing peace-of-mind that components are running clean and trouble-free for outstanding performance, long life and reduced maintenance and downtime, even in severe operating conditions. Qualified against the highest grease standards and designed for multiple-use applications, Synthetic Multi-Purpose Grease provides the ultimate in protection and convenience.

AMSOIL DOMINATOR Racing Grease is engineered with extreme-pressure additives to deliver excellent wear protection in heavily loaded, high-speed racing applications. Its high-performance anti-wear additive package helps ensure long component life. A high-viscosity-index synthetic base oil paired with a top-quality calcium sulfonate thickener known for its exceptional mechanical stability, high dropping point, high load-carrying performance, reduced wear and excellent resistance to water washout and corrosion. It offers excellent low-temperature pumpability and high-temperature consistency for dependable protection in all temperatures.

AMSOIL High-Viscosity Lithium-Complex Synthetic Grease is a lithium-complex-thickened grease blended with premium ISO 320 synthetic base oils. It is fully compounded with additives, providing superior extreme-pressure protection, oxidation resistance and corrosion protection. AMSOIL High-Viscosity Synthetic Grease is shear stable, maintaining its viscosity and consistency in the presence of mechanical activity. It also stays in place by resisting water washout. During high-temperature operation, AMSOIL High-Viscosity Grease’s base oils resist thermal breakdown, providing a thick film for excellent protection. AMSOIL High-Viscosity Synthetic Grease adheres to critical components in severe conditions to promote optimum operation, resulting in increased uptime and reduced repair and maintenance costs.

AMSOIL Synthetic Polymeric Truck, Chassis and Equipment Grease (GPTR1) delivers excellent wear protection and extreme-pressure performance over extended service intervals in medium- and heavy-duty applications. It combines select base oils, proprietary synthetic polymeric chemistry, an advanced additive package and a lithium-complex thickener for excellent impact resistance, reliable contaminant control and maximum longevity.

AMSOIL Synthetic Polymeric Truck, Chassis and Equipment Grease (GPTR2) delivers excellent wear protection and extreme-pressure performance over extended service intervals in medium- and heavy-duty applications. It combines select base oils, proprietary synthetic polymeric chemistry, an advanced additive package and a lithium-complex thickener for excellent impact resistance, reliable contaminant control and maximum longevity.

AMSOIL Synthetic Water-Resistant Grease is an extreme-pressure grease formulated specially for wet-duty performance. Composed of premium-quality synthetic base oils and calcium-sulfonate complex thickeners, Water-Resistant Grease provides exceptional film strength, shear resistance, adhesion properties and mechanical stability. Its water-washout and sprayoff resistance are outstanding for applications frequently exposed to water, mud, snow or ice, including ATVs, UTVs, snowmobiles and boat trailers.

AMSOIL Fifth-Wheel Grease: Fifth-wheel hitches must be lubricated in order to minimize wear between the fifth-wheel plate and the trailer, ensure the trailer can pivot behind the pull vehicle (increasing fuel economy and reducing abnormal steering-component and tire wear) and reduce the tendency toward jackknifing. AMSOIL Synthetic Fifth-Wheel Grease is a heavy-duty lubricant engineered to provide outstanding protection and performance in the heavily-loaded, harsh operating environments specific to fifth-wheel hitches used in trucking and trailer applications.

AMSOIL X-Treme Synthetic Food-Grade Grease is an ultra-premium aluminum complex grease designed for high levels of protection in food service and pharmaceutical industry equipment. USDA H-1 rated for incidental contact with food. It provides exceptional performance over a wide operating temperature range of -35°F to 350°F (up to 400°F in intermittent-use situations), making it suitable for both hot and cold applications.

AMSOIL Arctic Synthetic Grease is recommended for industrial machinery, heavy-duty automotive and industrial equipment, chassis, bearings, off-road and heavy equipment operating in arctic climates. It provides exceptional performance over a wide operating temperature range of -75°F to 315°F.

AMSOIL Semi-Fluid 00 Synthetic EP Grease is a lithium complex semifluid grease formulated with high-viscosity ISO-460 synthetic base oils. It is a problem-solving lubricant ideal for leaky gear boxes in industrial and fleet applications and for use in applications that are difficult to service. Primary grease recommendation for truck wheel hubs as outlined in RP 631, issued by The Maintenance Council of the American Trucking Association.

AMSOIL Synthetic Polymeric Off-Road Grease (GPOR1) combines an over-based calcium-sulfonate complex thickener and proprietary synthetic polymeric technology to provide outstanding performance in heavy duty off-road applications.

AMSOIL developed an exclusive synthetic polymeric system custom-built to provide performance benefits specific to off-road equipment. This synthetic technology helps give AMSOIL Off-Road Grease the ability to tenaciously stay in place and provide maximum pound-out resistance over extended service intervals, even in wet environments.

AMSOIL Synthetic Polymeric Off-Road Grease (GPOR2) combines an over-based calcium-sulfonate complex thickener and proprietary synthetic polymeric technology to provide outstanding performance in heavy duty off-road applications.

AMSOIL developed an exclusive synthetic polymeric system custom-built to provide performance benefits specific to off-road equipment. This synthetic technology helps give AMSOIL Off-Road Grease the ability to tenaciously stay in place and provide maximum pound-out resistance over extended service intervals, even in wet environments.

Canada

Canada United States

United States